Since the 1950s, the United States has begun to research and use composite insulators. At that time, epoxy resin casting structures were mainly used, and they were generally installed outdoors.

In the late 1960s, composite structural insulators made of resin-reinforced fiberglass core rods and polymer materials such as rubber or fluoroplastics as shed sheaths appeared, and were successively used in various industrial lines and test lines in more than 30 countries and regions. For operation, the rated voltage is 15-1500kV for AC and 400-500kV for DC.

Since the 1980s, the promotion and application of composite insulators has been very rapid. The United States is the earliest and most widely used country in the use of composite insulators. According to relevant information, by the end of 1989, composite insulators accounted for 20% of the insulator market, composite post insulators accounted for 33% of all post insulators, and rod-shaped suspension composite insulators accounted for 20% of the insulator market. 15% of type insulators, the use voltage level is from AC 115 ~ 765kV, DC to 500kV. The average operating time of rod-shaped suspension composite insulators has been 7 years, and the longest service life has reached more than 30 years. Among them, 78% of the users reported that the use was good, 18% of the users thought it was okay to use, and 4% of the users reported that there were problems.

In the mid-1980s, there were at least 2 million composite insulators in operation for transmission lines with a voltage level of 35kV and below in North America. Germany has accumulated experience in the operation of 150,000 composite insulators, and Switzerland has nearly 200,000 composite insulators that have been in operation for more than 10 years.

In 2008, China’s annual demand for composite insulators has exceeded 3 million, and the number of uses has become the second largest country after the United States. The annual demand will increase at a rate of more than 20% in the past 10 years. China will add 48,000 km of new transmission lines and electrified railway lines by 2010. According to the measurement, the insulators required for each kilometer of high-voltage transmission lines are 40,000 yuan, and nearly 2 billion yuan of insulator products are needed.

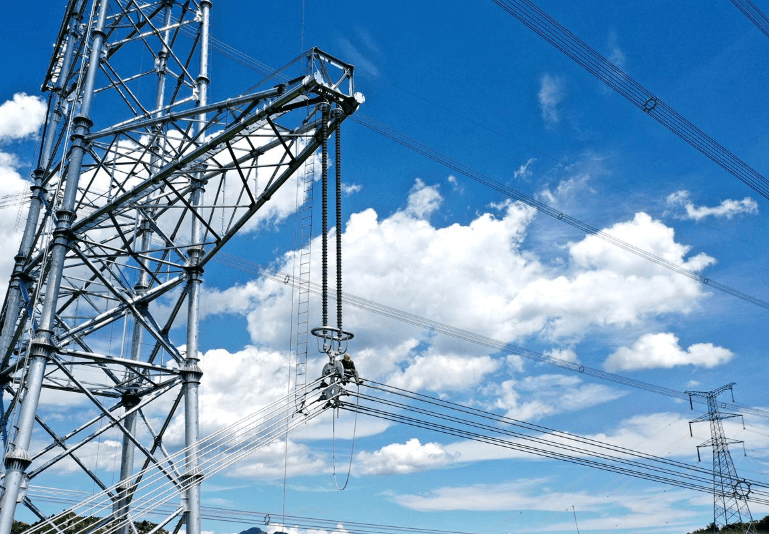

When China is building UHV AC and DC test bases and demonstration lines, more than 70% of the insulators use composite insulators. On the one hand, porcelain and glass insulators can no longer meet the needs of UHV line construction, and cannot cope with the problem of UHV pollution external insulation; on the one hand, the higher the voltage level, the higher the cost performance of composite insulators; on the other hand, China also wants to pass this demonstration. The construction of the line allows porcelain and glass insulators to do some tests and inspections in the UHV field. The research on composite insulators used in China’s power system began in the early 1980s. In 1988, China’s first composite insulator was officially produced.

In the spring of 1990, a large-scale pollution flashover occurred in North China Power Grid, and all the grid-linked composite insulators, although located in heavily polluted areas, withstood the test of that large-scale pollution flashover accident, and none of them had a flashover accident. Since then, composite insulators have been widely recognized by the power sector and power specialists, and the Ministry of Electric Power at that time even specially promoted them in polluted areas.

China’s composite insulator market is in short supply. Composite insulator factories have been built in China’s Hebei, Jiangsu, Shanghai and other places, and the competition in the composite insulator industry has begun.

China’s composite insulators have gone through the following three stages of development and have become a mature product.

(1)1981~1990 is the stage of development, achievement transfer and commercialization of synthetic insulators.

(2)The period from 1990 to 1994 was the stage of industrial trial operation of synthetic insulators.

(3)Since 1995, synthetic insulators have entered the stage of full practical use.

By 1995, composite insulators were not only widely praised by the operation department, but also attracted the attention of the design department. Composite insulators began to be used in large quantities in the commissioning and climbing of 500kV lines, and composite insulators were also used in batches or even in new lines.

Since 2006, or even earlier, China began to construct UHV lines. As an important component in UHV lines, composite insulators have received some attention. Major manufacturers have successively developed UHV AC-DC composite insulators, and in the subsequent Test bases and demonstration lines are connected to the grid in batches.