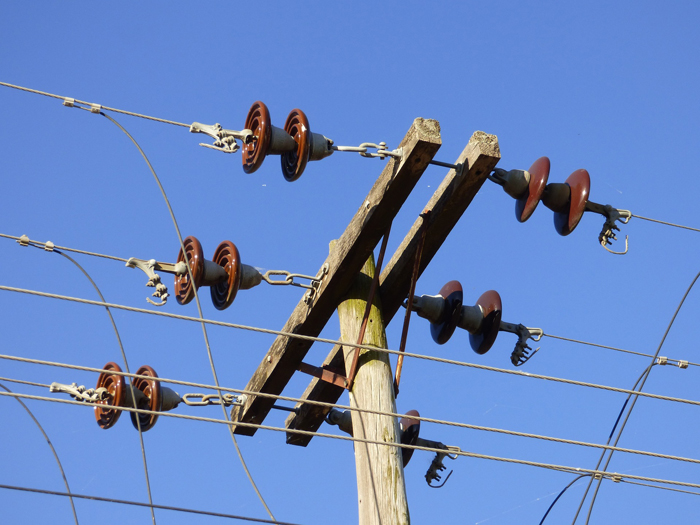

The porcelain disc insulator string, which assembled by several single disc insulator, is an essential component of electrical transmission and distribution systems. This type of insulator string is assembled by connecting individual

porcelain disc insulators in series using metal or composite rods, designed to effectively support and insulate overhead power lines.

Design and Structure:

Porcelain disc insulator ANSI 52-3 is a widely used model of porcelain insulators under the ANSI standard. Multiple ANSI 52-3 insulators are strung together to form an insulator string. Each disc insulator is designed to evenly distribute electrical field

stresses, preventing electrical arcing or leakage. These insulators are connected by rods made of galvanized steel or other suitable materials, providing mechanical strength and structural integrity.

Application:

Insulator strings are primarily used in medium to high voltage overhead transmission lines. They are mounted on supporting structures such as transmission towers or poles, providing crucial support to conductors and electrical insulation

between conductors and grounded structures.

Features and Specifications:

Voltage Rating: Porcelain disc insulator ANSI 52-3 insulator strings are designed to withstand specific voltage levels, ranging from several kilovolts to tens or even hundreds of kilovolts, depending on the application and system requirements.

Mechanical:Strength: The series configuration enhances mechanical strength, allowing the insulators to withstand environmental loads such as wind, ice, and the weight of conductors. This ensures the stability and reliability of overhead line

systems.

Environmental Resistance: Porcelain materials exhibit excellent resistance to environmental factors including moisture, UV radiation, and chemical pollutants. This durability helps maintain the performance and lifespan of insulator

strings under harsh outdoor conditions.

Series Configuration: The design of series-connected insulators ensures sufficient electrical clearance and even distribution of mechanical loads. This configuration minimizes the risks of electrical breakdown and mechanical failure,

ensuring safe and reliable operation.

Installation and Maintenance:

Installation and maintenance of ANSI 52-3 porcelain disc insulator strings require specialized skills and adherence to safety standards. Proper installation includes ensuring correct spacing between insulators, securely attaching them to

supporting structures, and maintaining adequate clearance from nearby objects. Regular inspections are essential to detect any damage or signs of aging that could affect performance or safety.

Conclusion:

In conclusion, porcelain disc insulator ANSI 52-3 strings play a crucial role in the infrastructure of electrical transmission and distribution networks. Their robust design, excellent electrical insulation properties, and ability to

withstand environmental stresses make them indispensable for ensuring reliable electricity transmission. As technology and materials continue to advance, these insulator strings evolve to meet the growing demands of modern global power

systems, contributing to efficiency, safety, and sustainability in power distribution.